Hexagon has officially released Cradle CFD 2024.2, introducing significant advancements across thermal-fluid simulation, meshing, data handling, AI-driven modeling, and real-time performance. This release strengthens Cradle CFD’s position as a leading solution for solving real-world problems in thermal management, battery safety, and flow simulations with precision and ease.

Table of Contents

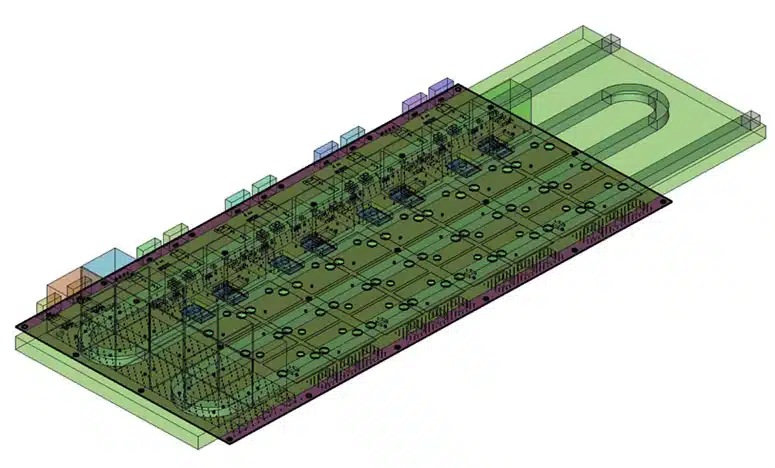

1. Next-Gen Battery Thermal Runaway Simulation

Cradle CFD 2024.2 introduces semi-empirical thermal runaway modeling for battery packs using ARC (Accelerating Rate Calorimetry) test data. Engineers can now simulate heat propagation from a single-cell failure across the battery array with high accuracy. The ARC data is imported, filtered, and smoothed automatically, defining transient heat generation with minimal effort—ensuring safer and faster battery system design.

2. Integrated Additive Manufacturing Workflow with nTop™

A standout feature of this release is the seamless integration with nTop™, enabling direct import of implicit parametric models into scSTREAM. This drastically accelerates the design-analysis loop for heat exchanger optimization. Engineers can run simulations and analyze multiple design variants in a fraction of the time compared to conventional workflows, making this a game-changer for additive manufacturing and thermal optimization.

Note: The interface tool for nTop is provided separately. Please contact cradle.support@mscsoftware.com for access.

3. AI-Powered Reduced Order Models for Real-Time Simulation

Cradle continues its collaboration with ODYSSEE to introduce machine learning-based Reduced Order Models (ROMs) for thermal-flow simulations:

- BCI-ROM in scSTREAM: A Dynamic Compact Thermal Model (DCTM) capable of predicting transient behavior of complex electronic devices under varying boundary conditions.

- 3D-ROM via POD-ARBF in scFLOW: Leveraging Proper Orthogonal Decomposition and Adaptive Radial Basis Function, users can now build ROMs from 3D field data to simulate the behavior of compact systems in real time.

These methods bypass the need for full transient analysis and are ideal for systems with multiple heat sources or regions of interest.

4. Smarter Parametric Studies and Automation

The parametric study capabilities in scFLOW have been enhanced with geometry modification via VBScript. A built-in “workflow wizard” helps set up Design of Experiments (DOE) with scMonitor, allowing users to monitor simulations and performance metrics seamlessly.

5. Advanced Meshing Tools for Faster and Cleaner Models

Cradle CFD 2024.2 delivers major improvements to scFLOW meshing, making it easier to prepare accurate and efficient computational domains:

- Curvature-based refinement: Automatically detects and refines highly curved areas.

- Periodic boundary mesh similarity: Ensures mesh compatibility across periodic interfaces to reduce numerical errors.

- Multi-GPH mesh import: Swap specific domain portions—such as rotating fan regions—without remeshing.

- Mesh quality table: Pinpoints problem areas by mesh quality criteria for quicker corrections.

6. Solver Speed & Stability Enhancements

scFLOW Solver:

- Overset mesh acceleration: Hole cutting in overlapping zones is now 10–30% faster.

- Parallel computing boost: MPI rank reordering improves inter-node communication on large core clusters.

- Improved morphing with RBF: Robust deformation using control points with user-defined motion.

- Custom convergence control: Define arbitrary variables to trigger convergence detection.

Time Averaging and Cycle Control:

Engineers now have granular control over time-averaged outputs. Save only necessary fields, reference averaged values in UDFs, and reduce file sizes—ideal for large-scale, multi-phase VOF simulations.

7. Expanded File Format and Data Handling Capabilities

- ODB++ import in scSTREAM: Directly bring in PCB design files, including component hierarchy, wiring, and thermal vias.

- CGNS (HDF5) and glTF support: Convert, import, and export across standard simulation and visualization formats using scCONVERTER and scPOST.

- Large-scale visualization: Preview cut planes, reduce memory usage, and speed up data access from cloud storage or remote servers.

8. Post-Processing Upgrades for Engineers and Designers

Cradle CFD 2024.2 enhances scPOST with intuitive and powerful tools:

- Multi-view analysis: Simultaneously display different camera angles, settings, and even different files—great for comparison and presentation.

- Turbo machinery visualization: Generate meridional and blade-to-blade planes for rotating machinery effortlessly.

- One-click streamline seeding: Automatically populate streamlines across selected surfaces.

9. Additional Engineering Improvements

scFLOW:

- Supports 64-bit mesh element limits, heat reactions, hypersonic inviscid flux, and dynamic adaptive mesh refinement.

- Enhanced anisotropic pressure drop modeling for porous media.

scSTREAM:

- Beta version of JOS-3 human comfort model introduced.

- ARM architecture support planned for December 2024.

scPOST:

- Particle count control added for DEM simulations, improving visualization performance.

Final Thoughts

Cradle CFD 2024.2 exemplifies Hexagon’s commitment to advancing simulation technology. Whether you’re designing batteries, optimizing thermal systems, or building smarter electronics, this release offers smarter workflows, faster solvers, and deeper insights than ever before.

Get Started with Cradle CFD 2024.2

- Ready to explore the latest features? You can access the Cradle CFD 2024.2 installer directly through the Software Download Center.

- Need help or technical guidance? Visit the official Cradle CFD support portal on SimCompanion for comprehensive documentation, updates, and expert assistance—or reach out to us for personalized help.