General Applications

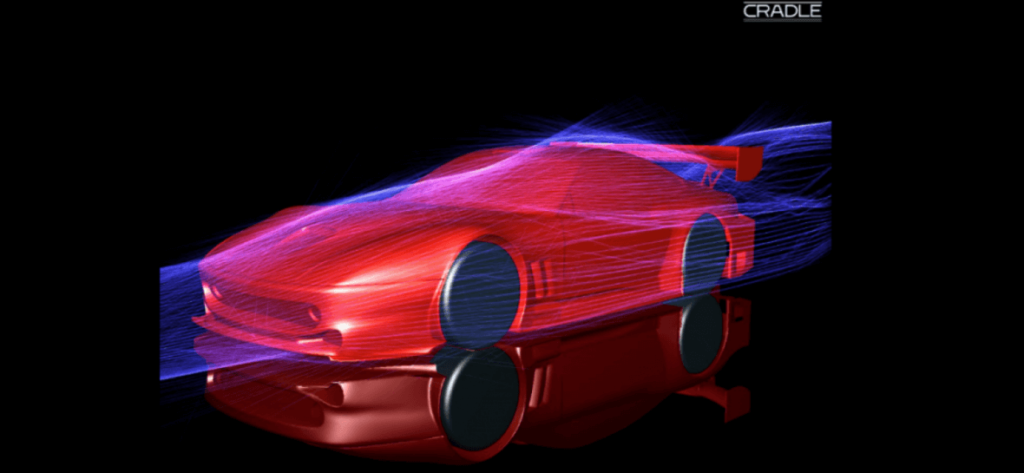

Vehicle Aerodynamics

The drag coefficient (Cd) and lift coefficient (Cl) are critical metrics for evaluating a vehicle’s aerodynamic performance. Traditionally, these coefficients have been determined through wind tunnel testing. However, SC/Tetra has been validated as a highly accurate tool for calculating aerodynamic performance, showcasing one of the key CFD applications in vehicle design, with minimal deviation from experimental data. SC/Tetra’s advanced solver is optimized to handle detailed modeling of underbody structures and piping systems while using minimal memory. At Software Cradle, we are committed to continuously enhancing the accuracy and capabilities of SC/Tetra. We also offer expert technical support, including conducting complex, high-level simulations for our clients.

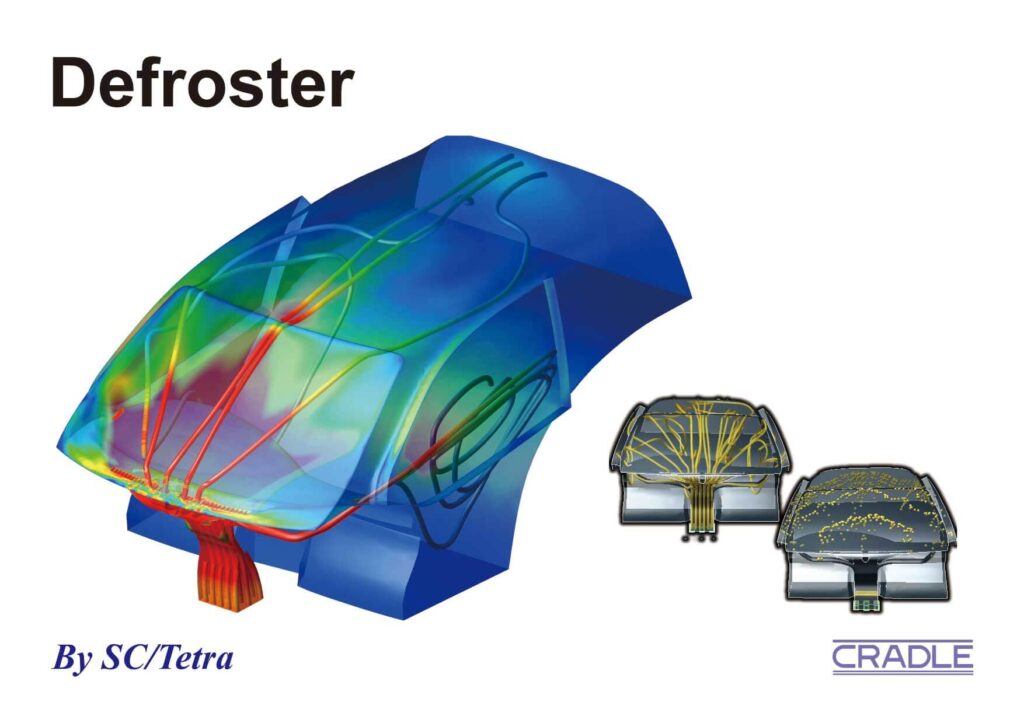

Passenger Comfort

In addition to vehicle aerodynamics, optimizing interior climate control systems is another essential application of Computational Fluid Dynamics (CFD). These CFD applications encompass interior heating and cooling, including the effects of solar radiation, as well as windshield defogging and defrosting. SC/Tetra excels in managing highly complex geometries, thanks to its advanced and robust grid generator and low memory consumption solver. Moreover, SC/Tetra offers unique capabilities for predicting occupant comfort through a fully coupled human body thermoregulatory model. This model accounts for the detailed human vascular system and individual physiological factors, providing a comprehensive analysis of comfort levels.

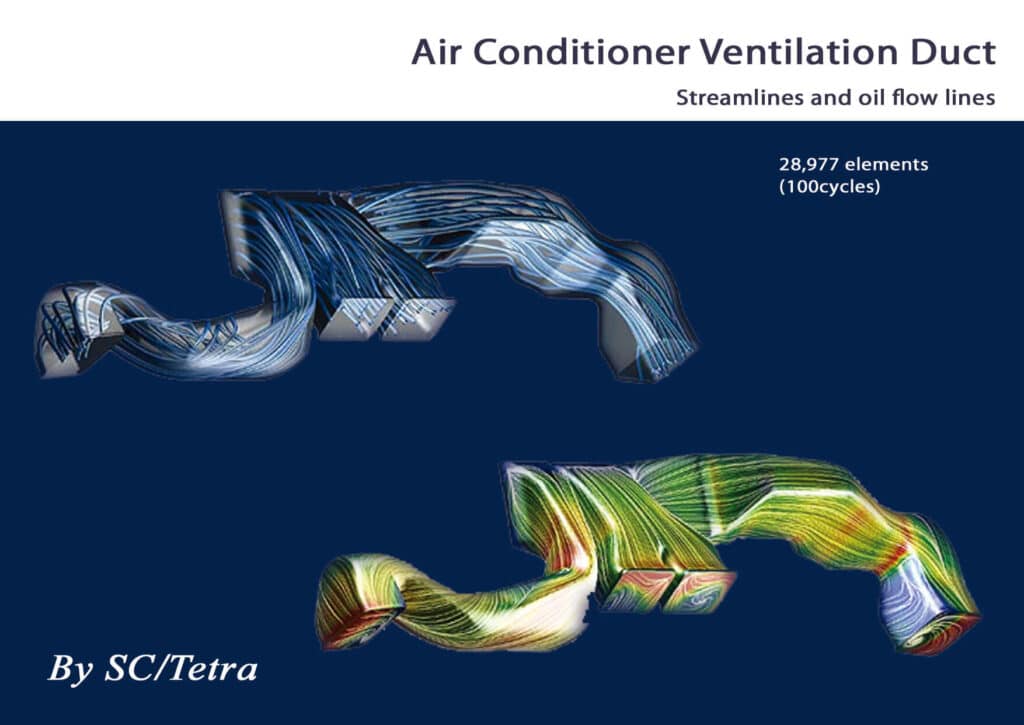

Air Conditioner Ventilation Duct

SC/Tetra is utilized in the design of air conditioner ventilation ductwork, highlighting another important area of CFD applications. Through CFD, it enables efficient computation of balanced air distribution, allowing for design optimization even in spaces with significant constraints.

Underhood Cooling

Engine compartment ventilation, including radiator cooling performance, is one of the critical CFD applications in automotive engineering. SC/Tetra is well-suited for accurate computation of highly complex geometrical models, encompassing the engine, radiator fan, accessories, and vehicle underbody details. This analysis can also include calculating the pressure drop across the radiator.

Side View Mirror

In addition to simulating vehicle aerodynamics, CFD is also used to optimize the shape of individual vehicle components that affect overall aerodynamics. One example is the side view mirror. The side view mirror must meet various design criteria, including proper positioning to reflect the correct views, minimizing drag, repelling water droplets on the mirror surface, and reducing aerodynamically induced acoustic noise. SC/Tetra enables the evaluation of different design concepts in a short amount of time.

Manifold

Intake and exhaust manifold performance are typically first simulated in a steady state to ensure uniform pressure distribution. Transient analysis is then used to determine the presence of any reverse flows. As part of CFD applications, an exhaust manifold should undergo both internal flow and thermal simulations to ensure appropriate material selection and thickness.

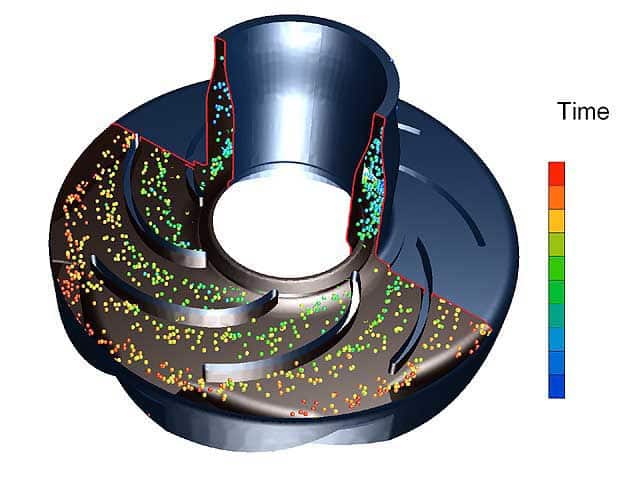

Torque Converter

The analysis of a torque converter used in a vehicle’s automatic transmission is among the specialized CFD applications that require calculations accounting for rotating boundaries. This allows for the evaluation of torque values as well as the pressure (force) exerted on each component.

Engine Valve

For engine valve analyses, the swirl ratio and tumble ratio are crucial parameters that significantly impact fuel mixture, combustion, and emissions, making them vital CFD applications for engine optimization. SC/Tetra is employed to calculate and optimize the design geometries of inlet and exhaust valves.

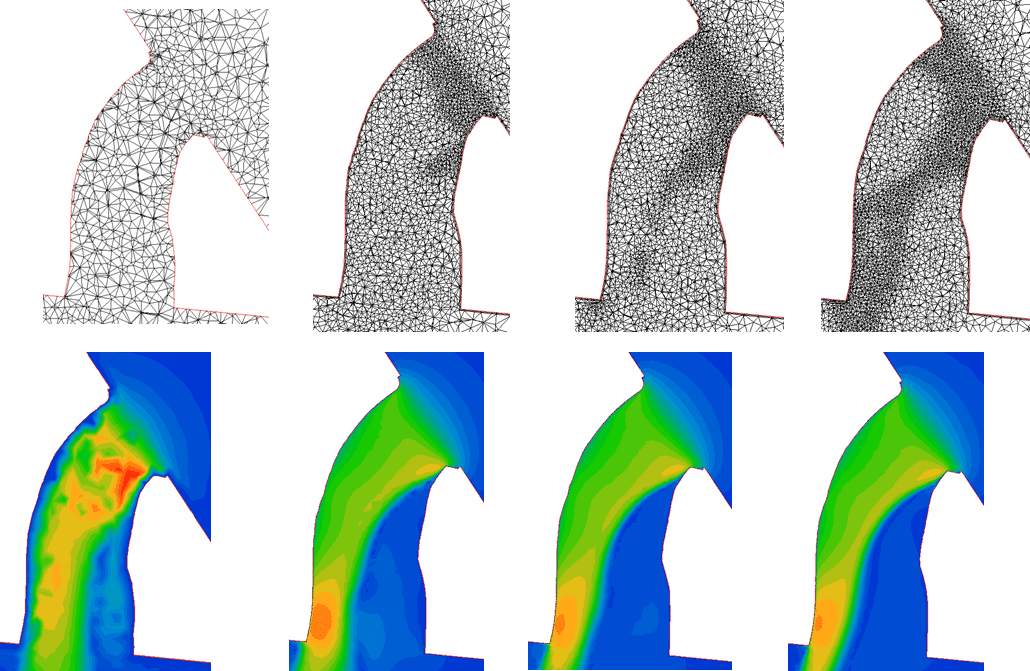

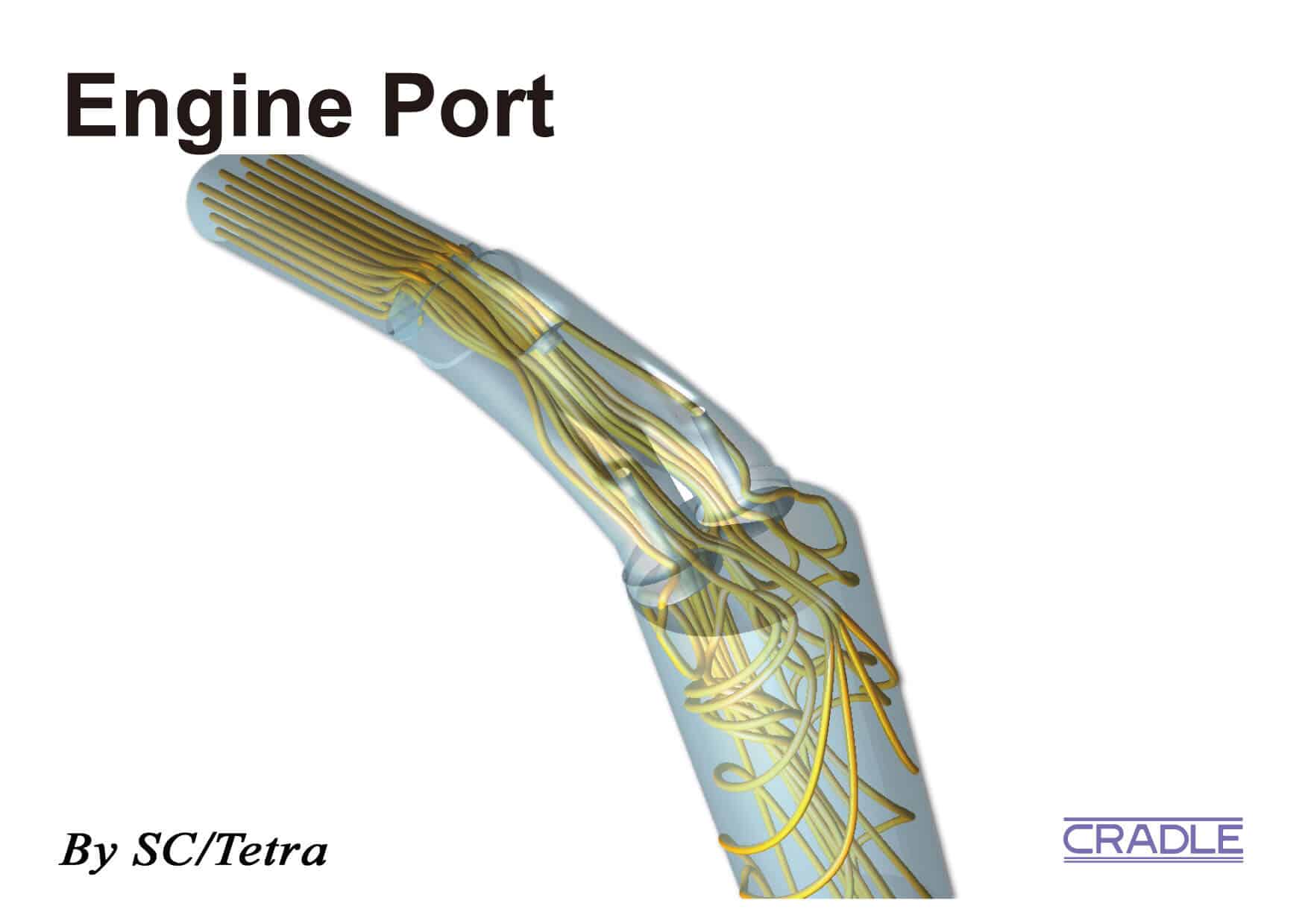

Analysis of Duct of Engine Port

Engine port flows can be analyzed using mesh adaptation analysis. This function automatically detects areas where the mesh should be more refined, based on analysis results. By re-generating the mesh and re-processing calculations, more accurate results can be obtained, independent of the analyst’s mesh generation skills.

Flow Analysis of Engine Port

This type of analysis is among the CFD applications designed to predict the inflow rate of air, which depends on valve lift and the degree of attachment. Analysis time and memory usage can be minimized by applying a 1/2 scale model when symmetrical geometry is used. Automatic script processing is also possible, using valve lift and degree of attachment as parameters.

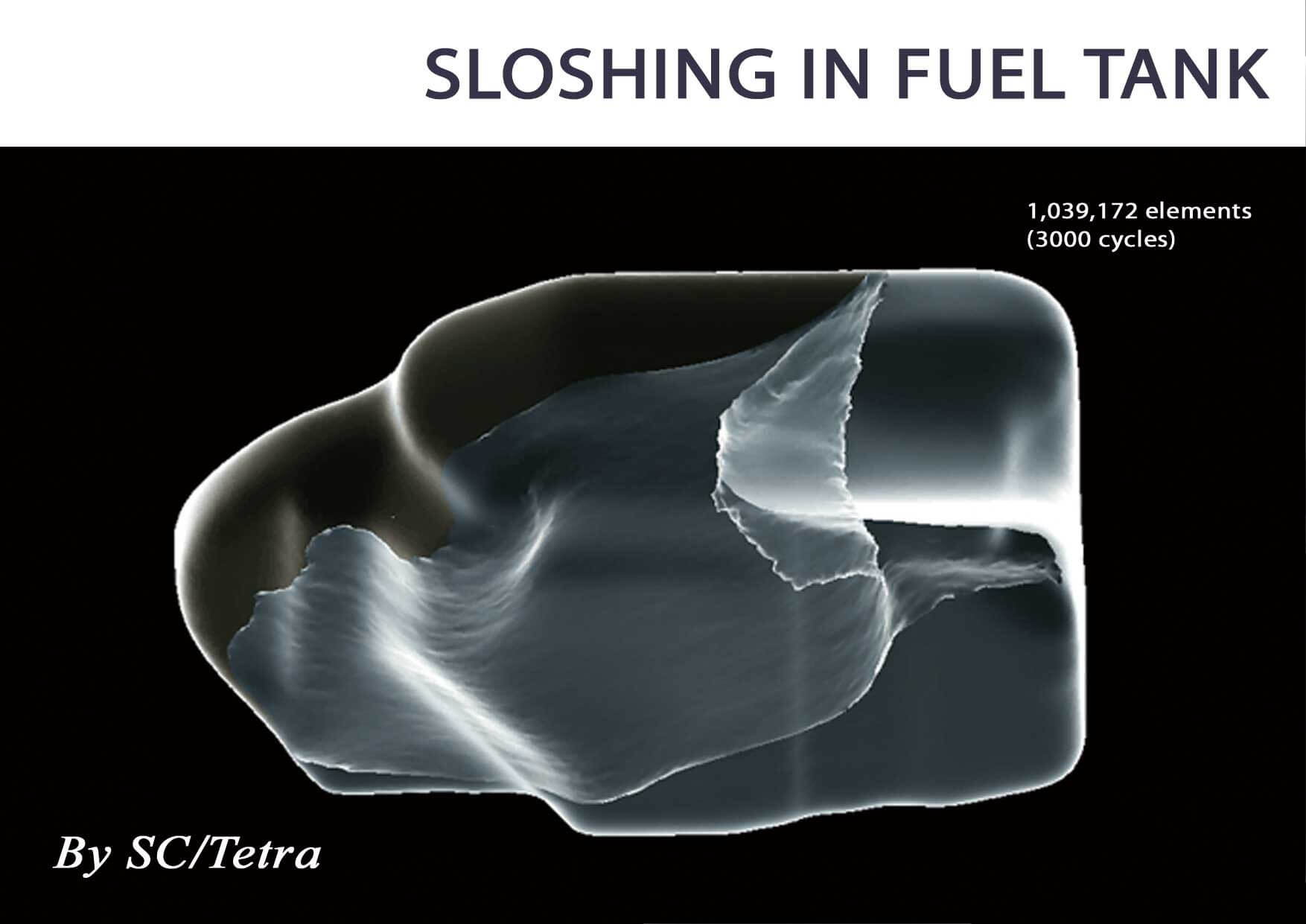

Analysis of Gasoline Sloshing of Tank

Fluid sloshing occurs within gasoline tanks of vehicles and ships due to external periodic vibrations, which can lead to tank damage or fuel leakage. This is one of the CFD applications where the free surface function called VOF (Volume of Fluid) is used to predict fluid vibrations and changes in container pressure. Design engineers can identify the ideal container geometry that prevents load concentration by examining the flow and pressure.

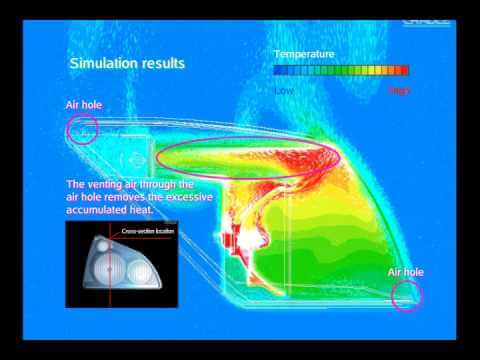

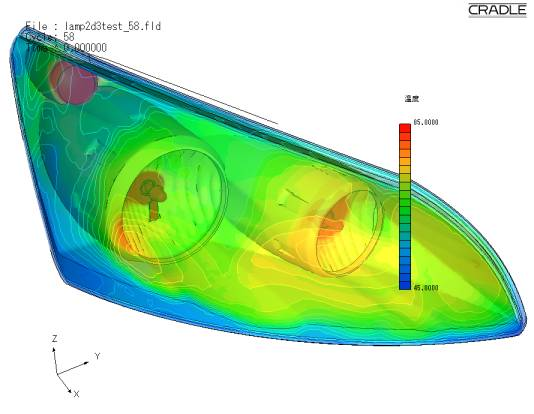

Vehicle Headlights

Thermal management is crucial due to the high output characteristics of vehicle headlights, especially when LED headlights are used, which have a low heat-resistant temperature. Heat from the light source is emitted to the open air as radiant energy, along with heat conduction and convective heat transfer. Highly accurate temperature prediction is possible by accounting for the reflectivity of the reflector and the absorbance degree of the cover material.

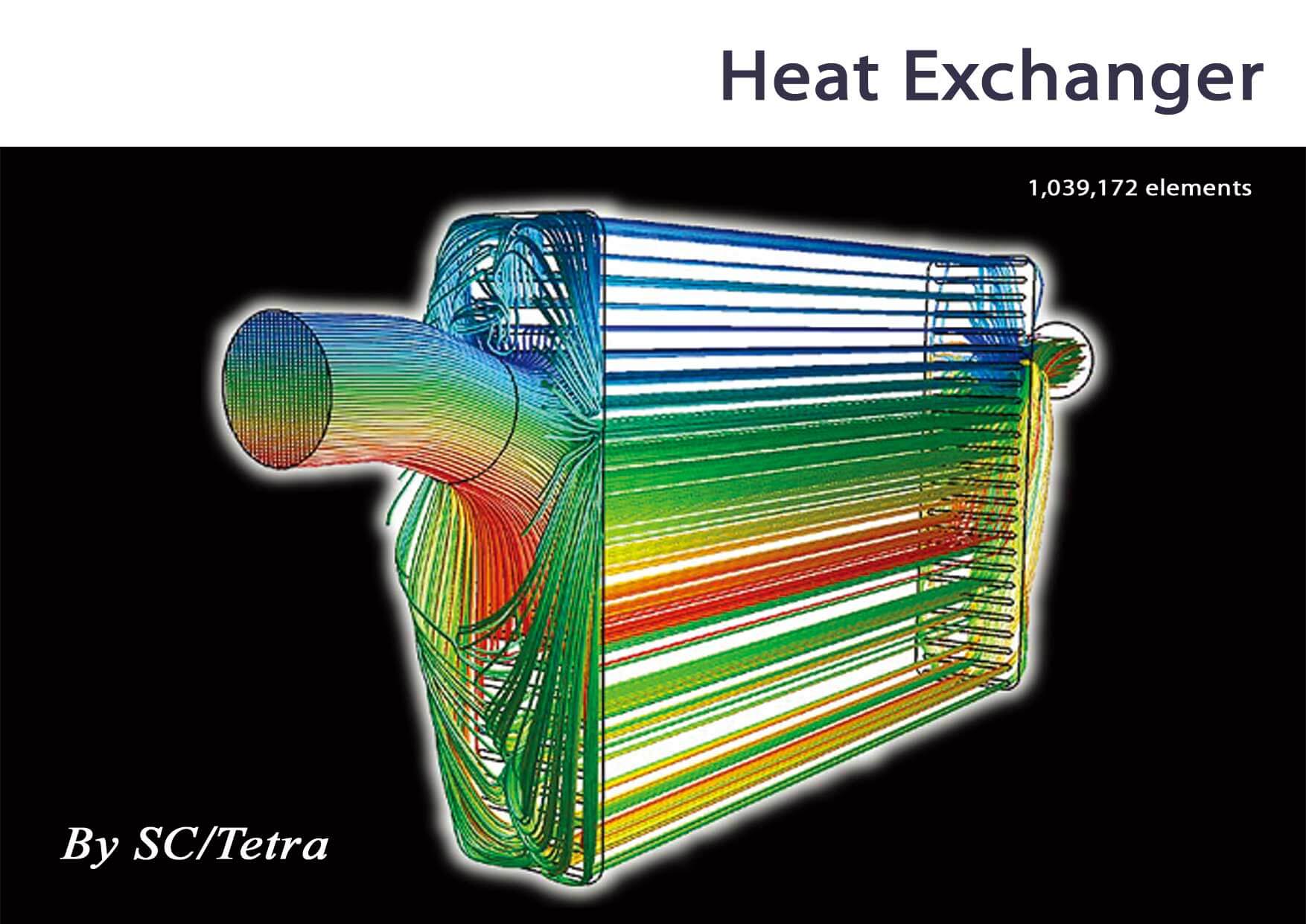

Heat Exchanger (Radiator, Inter-cooler, Oil Cooler)

A CFD simulation of a heat exchanger, such as a radiator, considers two working fluids—typically air and water/coolant. CFD applications are essential in determining the efficiency of heat exchangers, which is directly influenced by the velocity of the fluids at the wall. Additionally, CFD predicts whether the coolant flow is uniform within the heat exchanger. Coolant flows in the water jacket of an engine block can also be analyzed, as the underlying mechanism is fundamentally the same as that of a heat exchanger.

Analysis of the Fluid Flow inside In-cylinder (Mesh Element Distribution and Surface Pressure Distribution)

Complicated transient flow occurs in cylinders due to the opening and closing of engine valves. This valve operation can be analyzed using the overset mesh function, which calculates layered in-cylinder and valve mesh elements. By accounting for contact between objects—an aspect that was previously difficult to examine—this analysis allows for a more accurate prediction of the flow field influenced by the opening and closing motions.

Aerodynamic Analysis of Formula Car (Surface Pressure and Streamlines)

In Formula car races, reducing air drag is crucial for achieving faster and more stable driving. Simulations of airflow over a racing car help to understand the mechanisms behind air drag by visualizing the complex flow patterns and pressure forces on the car body, thereby contributing to the improvement of the vehicle’s shape.

Analysis of the Air Flow in Large Vehicle Interior (Streamline and Distribution of Surface Temperature)

The thermal comfort of a bus’s interior space can be evaluated by considering air-conditioning effects and thermal loads. Passengers can be represented using JOS (thermoregulation) models, which account for blood circulation, the body’s thermal management functions, and the effects of clothing. This analysis allows for the assessment of passenger comfort by calculating air temperature, as well as the skin temperature and perspiration levels of passengers within the vehicle’s interior.

Analysis of a Water Jacket

A water flow channel placed for cooling the heat from engine cylinders is called a water jacket. A water jacket is designed in such a way to make the flow speed fast at the portions that particularly need to be cooled, and also to avoid air pools. In SC/Tetra, mesh can be generated automaticA water flow channel used for cooling engine cylinders is known as a water jacket. A water jacket is designed to ensure high flow speeds at critical areas that require cooling and to prevent air pockets. In SC/Tetra, the mesh can be automatically generated even for such complex, large-scale geometries.ally even for this kind of complicated, large-scale geometry.

Thermal Analysis of a Vehicle Headlamp (Temperature Distribution)

CFD applications in thermal management are crucial due to the high output characteristics of vehicle headlights, especially when LED headlights are used. Heat from the light source is emitted into the open air as radiant energy, along with heat conduction and convective heat transfer. Highly accurate temperature predictions are possible by accounting for the reflectivity of the reflector and the absorption properties of the cover material.

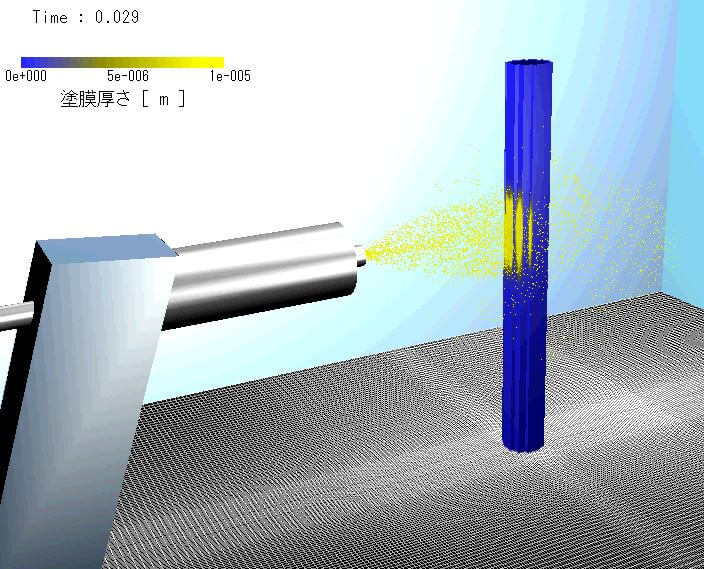

Analysis of Liquid Film

The effects of paints can be analyzed using the liquid film model, representing another innovative example of CFD applications. Spray paints from a nozzle can be modeled, where liquid particles form a liquid film upon reaching the wall. The liquid film model requires less computational load compared to the free surface analysis function, which considers surface tension and contact angle, making it ideal for analyzing the spread of thin liquid films.

Analysis of Electrostatic Spray

This is one of the CFD applications where particle tracking is used to analyze the spraying effects of paint from a spray gun. The effects of paint particles, which are emitted through an electrostatic field created by the voltage applied from the spray gun, can be evaluated while they are exposed to electrostatic forces. It is also possible to calculate the adhesion position of the paint on the target object and the thickness of the adhered layer.

Heat Sink

Predicting the performance of a single heat sink is one of the fundamental CFD applications in thermal simulation Thermal conduction is influenced by the spacing and thickness of the fins, while the heat-transfer coefficient is affected by the air velocity over the fin surface. Some heat sinks are integrated with a fan. SC/Tetra can simulate these systems by incorporating the fan rotation model, a primary source of cooling. The steady-state performance of the heat sink is calculated quickly, though fan rotation introduces a transient component.

Power Supply Unit

Among the many CFD applications, analyzing the power supply unit, which transforms voltage and emits large amounts of heat, is crucial for ensuring efficient heat dissipation. HeatDesigner reliably computes natural heat dissipation using predetermined calculation parameters tailored for electrical and electronics equipment.

Analysis of a Sirocco Fan

The flow of a sirocco fan can be analyzed to examine the relationship between rotational speed and output flow rate. By using the moving region function to simulate blade rotation, analysts can visualize the flow and pressure, enabling improvements to blade geometry. Additionally, the aerodynamic noise function can be used to identify fan-generated noise.

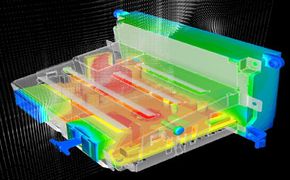

Flow Analysis inside a Chassis (Particle Tracking)

This is a simulation example of electronics cooling using fans, illustrating another of the diverse CFD applications in thermal management. For effective forced air-cooling design, it is crucial to select the most appropriate type of fan and determine its optimal position. Through thermal analysis, engineers can verify whether the output airflow rate and velocity directed at the cooling target components meet the required specifications. Additionally, the overall device can be optimized by evaluating the ideal geometry of heat sinks along the airflow paths.

Car Audio and Navigation Systems

Car audio and navigation systems generate a significant amount of heat, subjecting the interior of the automotive dashboard to extremely high temperatures. Optimal system integration requires thorough analysis of potential thermal issues. HeatDesigner and scSTREAM are well-suited for this type of analysis, which demands a high degree of accuracy. Both tools efficiently handle large models, making them ideal for resolving fine geometric details.

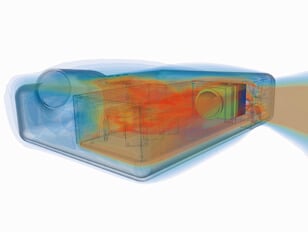

Projector

Due to the increasing demands for miniaturization and improved output power, ensuring effective heat dissipation is critical in projector design. Early evaluation of fan design and component layout, key CFD applications, allows designers to assess and implement strategies to enhance heat dissipation efficiency.

Smartphone

Thermal design is one of the essential CFD applications when developing a smartphone, as the sealed casing can lead to increased temperatures. By simulating thermal flow before manufacturing, engineers can adjust component layout and materials, optimizing the overall design.

Compressible Flow Analysis of a Hypersonic Transport Plane

This is an example of analyzing supersonic transport. As flying speed exceeds the speed of sound, fluid pressure increases, leading to phenomena such as shock waves that do not occur at lower speeds. Accurately predicting changes in the flow field under these conditions highlights one of the critical CFD applications in aerospace engineering, requiring a method that accounts for fluid compressibility.

Analysis of the Flow inside Gear Pump (Mesh Element Distribution)

Gear pumps are widely used as constant volume pumps in hydraulic power units for industrial machinery. In this type of analysis, the surrounding fluid is transferred as the mesh elements of the gears rotate. This type of analysis is one of the specialized CFD applications where the overset mesh function accurately accounts for the effects of gears engaging with each other.

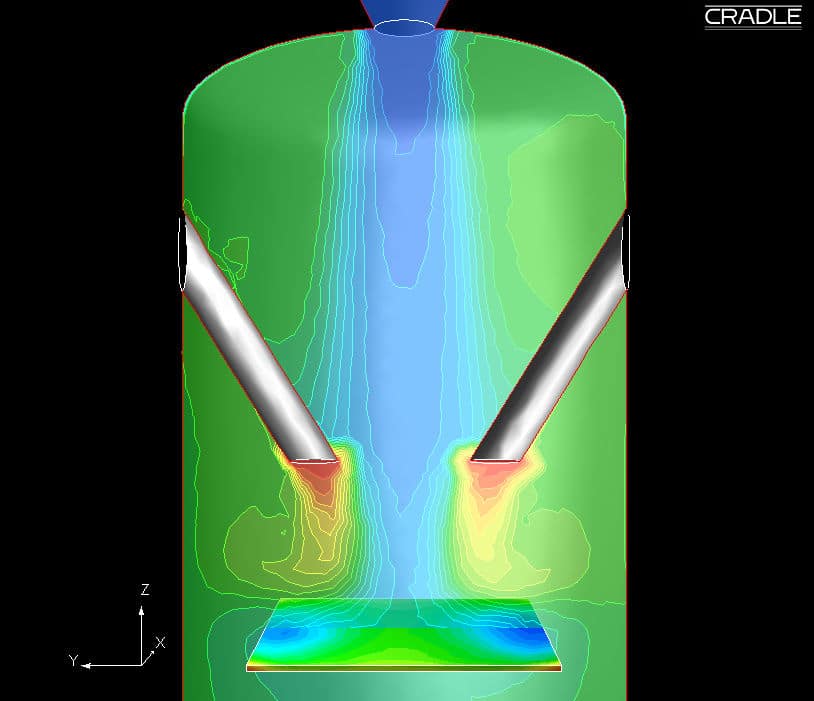

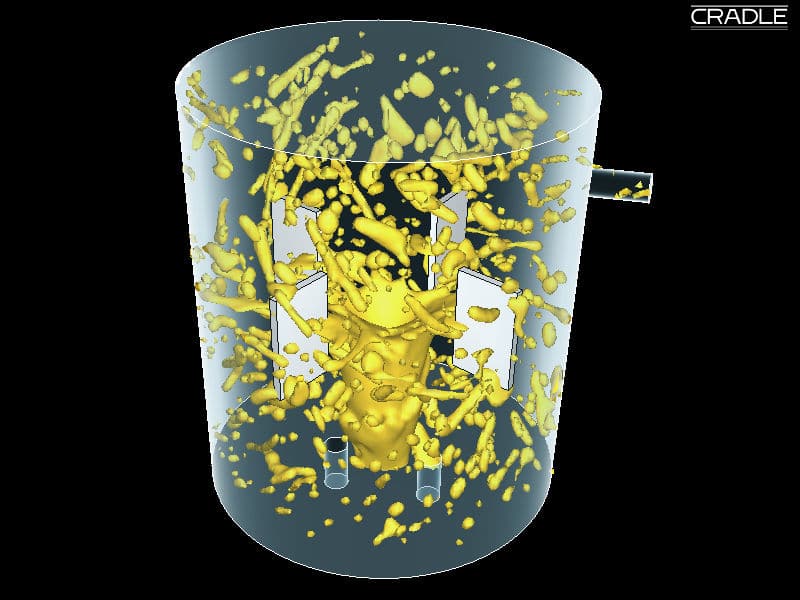

Analysis of a Mixing Tank (Mesh Element Distribution)

Mixing tanks are essential in various industrial processes. In this type of analysis, the mesh elements of the blades rotate, applying force to the surrounding fluids to create a mixing motion. The overset mesh function can be utilized to account for near or direct contact between blades when multiple blades are involved, as shown in the diagram.

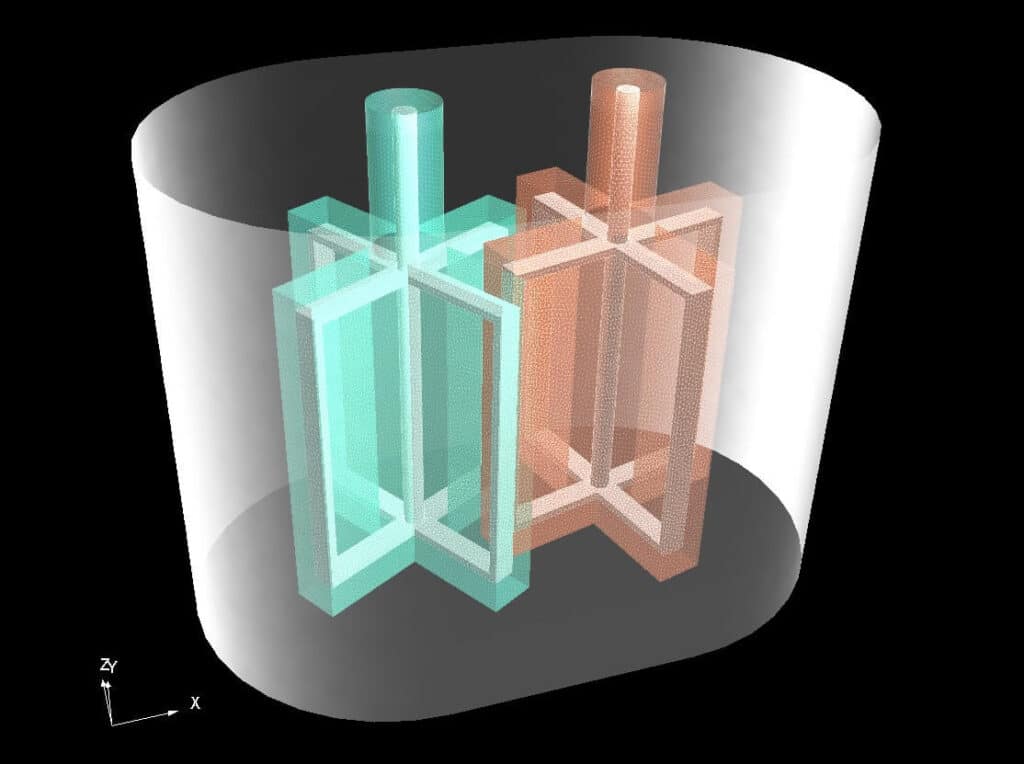

Analysis of Air Flow Generated by Roots Blower

A Roots blower is a pump that performs air intake and exhaust using a pair of non-contact, counter-rotating rotors. In this analysis, the mesh elements move as the rotors rotate. By using the overset mesh function, it is possible to accurately account for the effects of the rotors engaging with each other.

Flow Analysis of a Heat exchanger Fan for Refrigerator

In CFD applications, the flow of a cooling fan is determined by its blade geometry, the shape of the fan, and its allocated position. Using SC/Tetra, highly accurate flow analysis can be conducted, exemplifying one of the numerous CFD applications that account for the effects of surrounding device shapes and airflow.

Room Ventilation I

scSTREAM can be used to evaluate air-conditioning performance within a room in a house, office, or any large interior space. This fluid analysis calculates the distribution of air velocity and temperature throughout the design space, allowing for the determination of exact numerical values within any specific area. This method is much more precise than conventional thermal loading calculations. CFD also enables the inclusion and calculation of gas concentrations, solar radiation effects, and dew condensation. Additionally, scSTREAM is frequently used for analyzing clean room designs, which require precise air control.

Room Ventilation II

scSTREAM automatically calculates heat generation from sunlight using a solar radiation function. Users are provided with parameters to control solar radiation, including transmission rate, glass absorptivity, and the absorptivity of surfaces exposed to sunlight. By incorporating specific heat considerations, scSTREAM can also be used to evaluate the performance of a heat storage system that accumulates solar energy during the day and utilizes it at night. Additionally, scSTREAM can account for thermal buoyancy, such as natural ventilation caused by temperature differences throughout a house.

Gas flow in an Underground Parking Area

CFD is used to determine the optimal location and arrangement of exhaust fans in an underground parking area. For complex parking configurations, it is particularly important to avoid the accumulation of gas flow. scSTREAM generates an index value to quantify ventilation efficiency. In addition to standard computations of gas flow and gas concentration, users can easily compare the efficiency of various fan arrangements and performance levels.

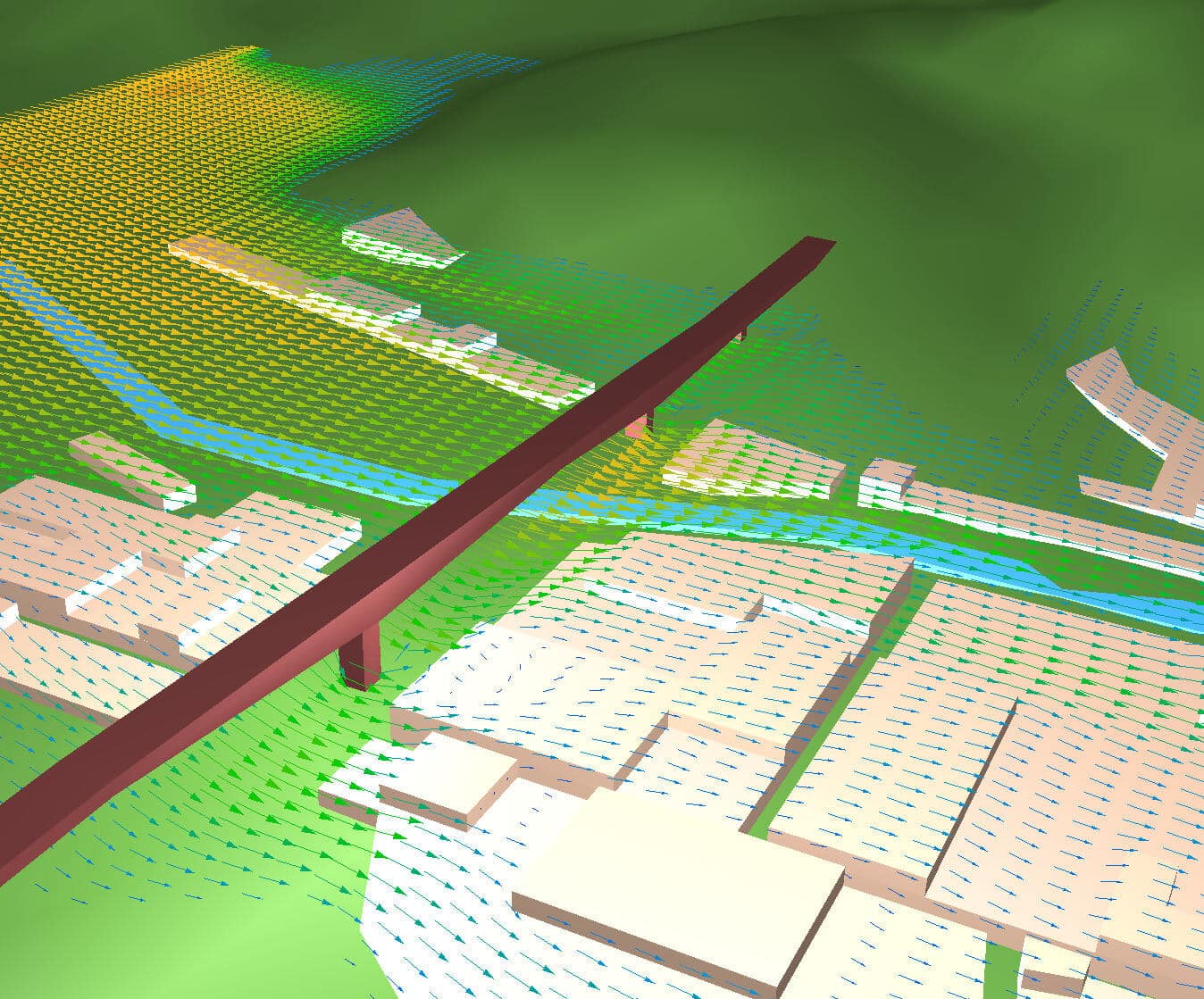

Air flow around Buildings

High-rise communities are subject to the complexities of wind patterns, both influencing and generating strong winds. It is crucial to analyze the wind environment before construction, as making adjustments afterward can be difficult and costly. scSTREAM can simulate accurate geometries by importing numerical maps (GIS format) for a specific building and its surrounding structures.

Exhaust heat and Smoke

CFD can be utilized to analyze the diffusion of plant stack gas and exhaust heat into the surrounding environment. It is used to predict gas concentration at different altitudes. This analysis helps evaluate the efficiency of specific cooling tower arrangements or exterior air conditioning units.

Ventilation System

CFD is used to evaluate the performance of ventilation systems. SC/Tetra is employed when the analysis involves complex shapes, such as the interior and outlet of an air conditioner. scSTREAM is used for analyzing surrounding airflow or for simpler geometries.

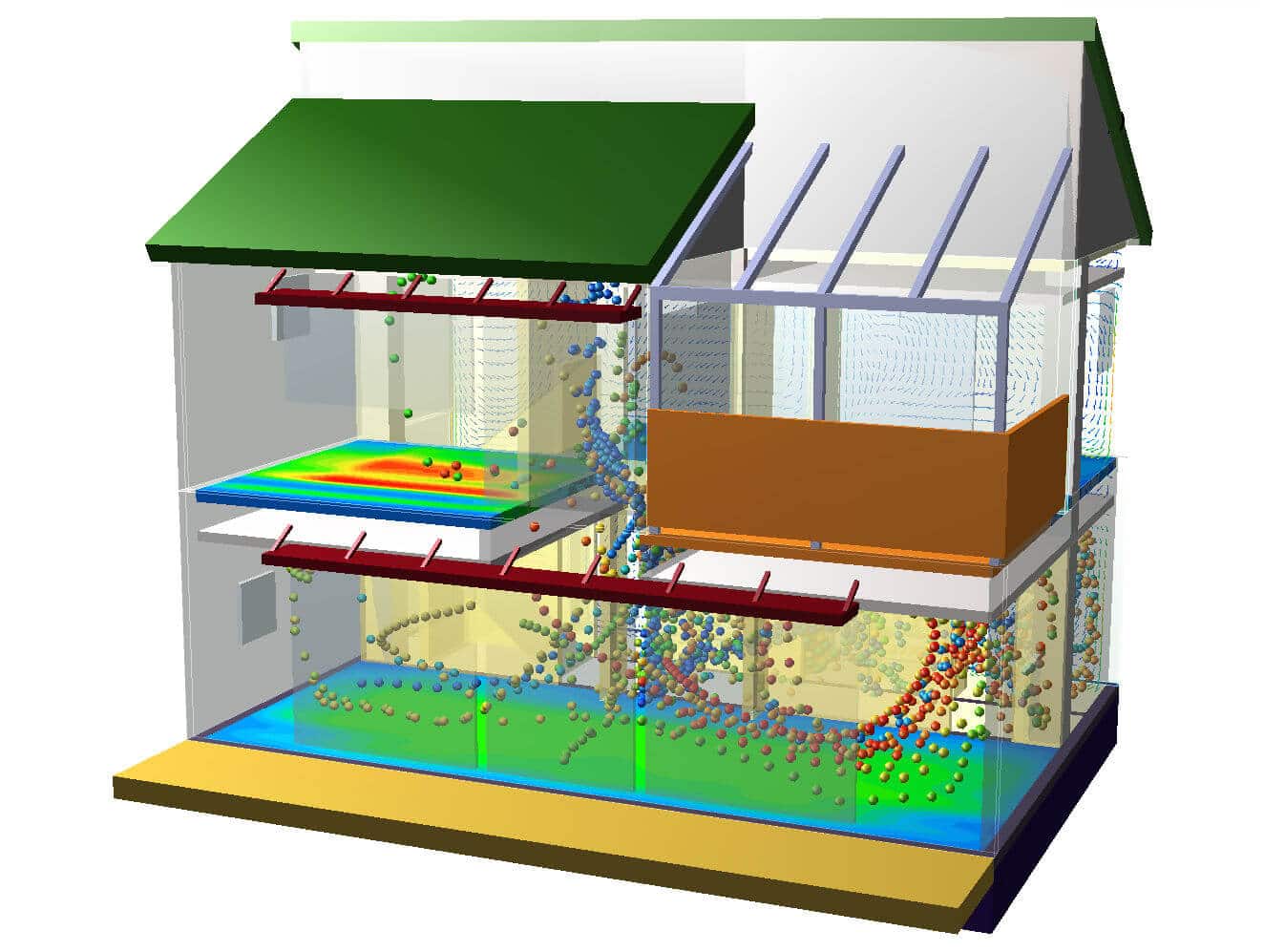

Paint Booth

A paint booth requires precise control of airflows, an area where CFD applications play a crucial role, similar to clean room environments. Accurate airflow ensures that paint reaches the target part and is not carried away into the exhaust. scSTREAM can be used to simulate particles, allowing for the inclusion of coupling effects between the airflow and particles, which ultimately determine the particles’ final destination.

Airflow around Bridge

Windy environments are common in valley-shaped terrains. A wind analysis should be conducted before any construction in these areas. scSTREAM can import terrain geography from map data and calculate wind pressures on buildings and bridges.

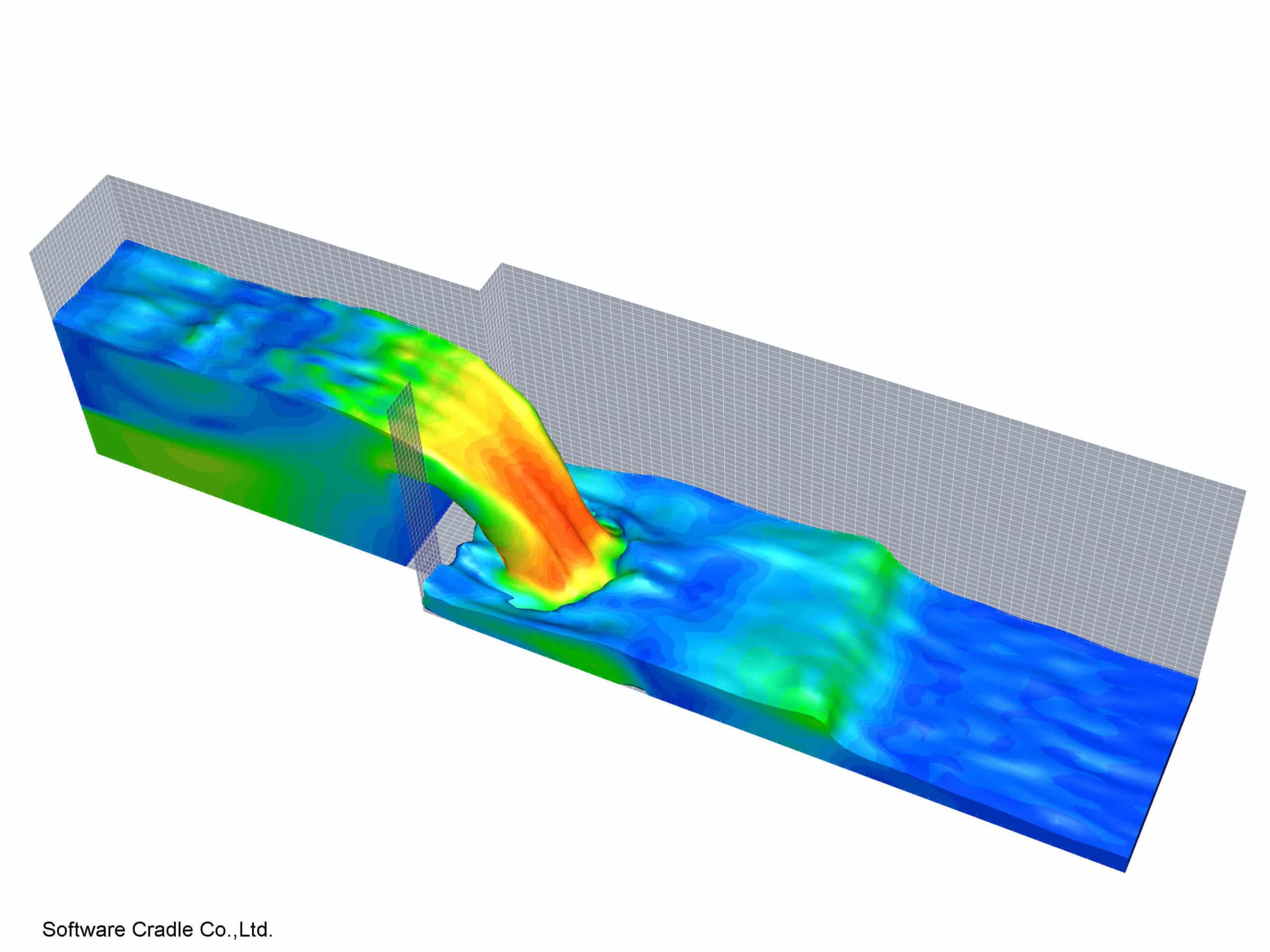

Water Flow over a Dam

Among CFD applications, scSTREAM and SC/Tetra can perform free surface analyses to calculate fluid surface shapes, essential in scenarios like water flow over a dam.

Flow around a Water Gate

Using the moving object function, SC/Tetra can calculate the fluid flow field associated with closing a water gate. CFD applications are vital for analyzing flow around a water gate, including pressure fluctuations and changes in water surface elevation.

Analysis of Thermal Environment of a Data Center

In a data center where a large number of servers must be adequately cooled, it is vital to maintain a constant room temperature. Thermo-fluid analyses can evaluate whether design parameters, such as air-conditioning performance, vent allocation, and appropriate spacing between servers, meet the necessary requirements.

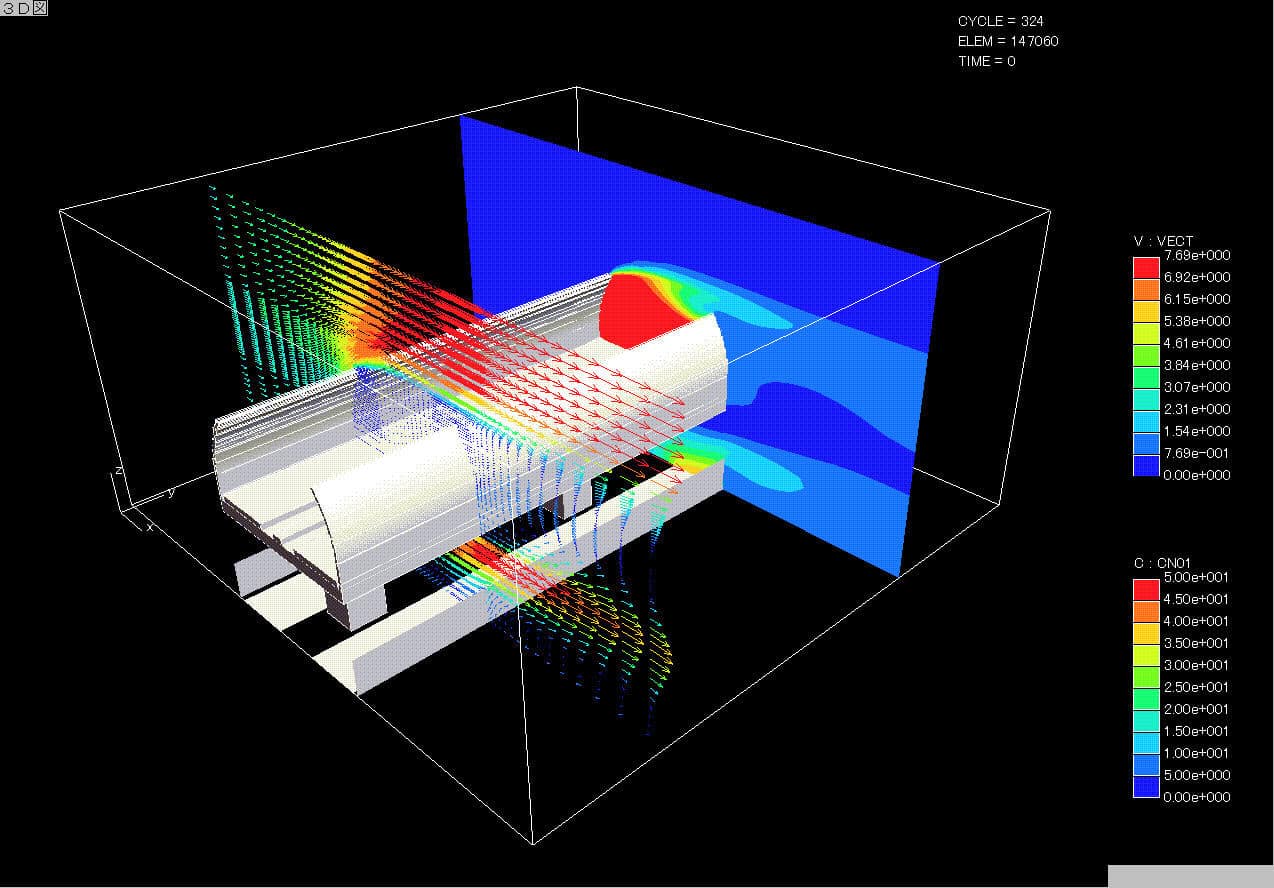

Analysis of Air Flow inside Clean Room (Speed Vector and Concentration Distribution).

In a cleanroom, the number of airborne particulates is kept below a specific level, with temperature, humidity, and pressure also carefully regulated. Using scSTREAM, it is possible to model particulates as diffusive species or particles and predict how air contaminants distribute and behave within the space.

Analysis of Car Exhaust Diffusion in an Expressway

Car exhaust from highways drifts over roadside barriers and disperses into the surrounding environment. By analyzing the advective diffusion of exhaust gases and the influence of wind on their flow, it is possible to predict the impact on nearby environments and residents. This analysis aids in assessing and mitigating potential air quality issues in areas adjacent to highways.

Analysis of Humidity in Indoor Space Facilitated with Humidity Conditioner

A humidity conditioner can help maintain a comfortable indoor environment and dry wet laundry on rainy days. However, its use can increase room temperature due to the latent heat generated while reducing humidity levels. With scSTREAM, it is possible to account for these effects and perform detailed humidity analyses of indoor spaces, ensuring optimal comfort and efficiency.

Axial Fan

Fluid flow analysis of an axial fan is challenging because the blade shape significantly affects performance. Accurate geometry representation and grid generation are critical. Starting from CAD data, SC/Tetra’s automatic mesh generator can create the computational mesh in a matter of hours, whereas most conventional CFD software may take weeks. SC/Tetra simulates rotating blades using the rotating boundary (ALE) function and can perform a preliminary steady-state analysis using only the blade’s rotational forces.

Sirocco Fan

SC/Tetra significantly reduces the time required to simulate a sirocco fan or a propeller fan. A transient analysis using the ALE function (Arbitrary Lagrangian-Eulerian for moving and/or rotating boundaries) provides more accurate details compared to a basic steady-state analysis.

Blower

A blower moves the working fluid with rotating blades, similar to other fans. SC/Tetra can model both gases and liquids.

Exhaust Fan

The shape and number of blades significantly affect the performance of a turbofan. SC/Tetra can evaluate several different cases in a short time by allowing models to be built with changes only to the rotating parts and their area.

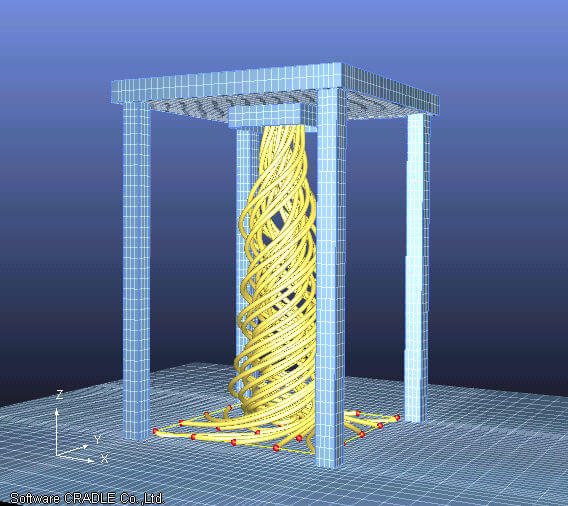

Vortex Blower

The internal flow of a vortex blower, which can rotate in either direction, is highly complex and can only be effectively visualized using CFD. CFD is invaluable for making this intricate flow visible, allowing users to understand the basic flow structure and underlying physics.

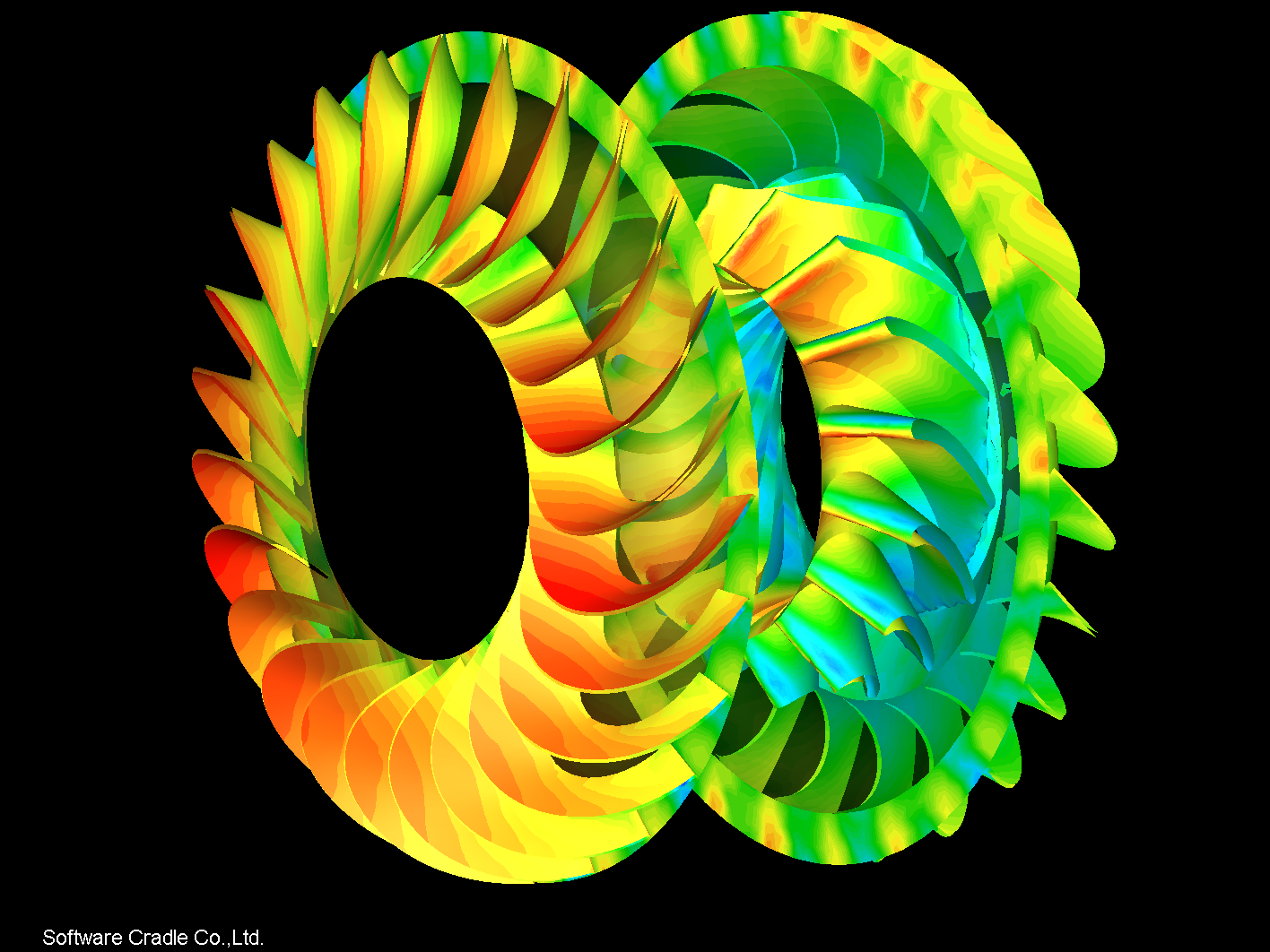

Multi-Stage Pump

The computation of fluid flow through fans and turbines can be time-consuming due to the transient phenomena occurring between the rotating and stationary components. However, SC/Tetra offers convenient functions designed to facilitate these analyses. These include the axial symmetric condition, periodic boundary conditions, and the ability to treat the rotating force as a rotating object rather than simulating the actual rotation. These functions significantly reduce calculation time while still accurately simulating the physics.

Die Coating

CFD analysis is also applied to the dye coating process, which uniformly coats materials with a dye liquid (paint) using wall movement. The free surface condition is used at the liquid/air interface, as the thickness of the liquid is the primary parameter being calculated. CFD enables parametric analyses to evaluate the effects of changing factors such as the velocity of the moving wall, wall roughness, viscosity, and the velocity of the liquid.

Chemical Vapor Deposition

CFD is used for analyzing the Chemical Vapor Deposition (CVD) process, which is employed to generate thin films, such as silicon, on printed circuit boards. SC/Tetra can handle both multiple-gas mixing analysis and single carrier gas analysis.

Mixing Tank

For a mixing tank that combines multiple materials, SC/Tetra is used to evaluate the performance of the mixing blades and tank design. scSTREAM can also be used to evaluate the mixing of multiple materials. These tools can simulate a wide variety of chemical phenomena by incorporating additional functions such as chemical reaction, particle tracking, and multi-phase flow, alongside standard thermal and fluid analysis.

Case Study Interviews

Casestudy: Improving Thermal Comfort in Thailand with scSTREAM

Case Study: Raintree Kindergarten – GreenDwell Thailand

Optimizing Shrimp Freezer Design with SC/Tetra at Khon Kaen Univ.

fdsa